The company carries out its manufacturing activities in Romania through a workshop located in Bucharest (WTB) and a river front facility in Oltenița (WTO), directly connected to the Danube river.

The strategic location of our facilities allow us to optimally handle long lead and critical products without limits of weight and size.

WTB

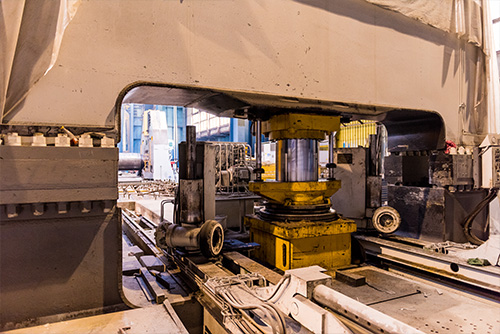

Our ultra-modern workshop in Bucharest, part of the IMGB industrial complex, is equipped with very efficient technologies and machines to optimize our production capacity.

| Covered Area | 30.500 sqm |

| Uncovered Area | 19.000 sqm |

| Maximum Height | 40 mt |

| Under Hook Maximum Height | 27.8 mt |

WTO

Our workshop WTO is located in the port of Oltenița (app. 60 km from Bucharest), where we also own a private River Port with access ramps to the river for roll-on and roll-off operations.

| Covered Area | 7.730 sqm |

| Uncovered Area | 71.300 sqm |

| Maximum Height | 28 mt |

National Company “Administratia Porturilor Dunării Fluviale” S.A. granted Walter Tosto WTB the right over ramps usage in the port of Oltenița for roll-on and roll-off operations (agreement n. 2251).

The Roll-on/Roll-off service of the ramps is subject to their availability at the time of request (*)

The ramps are available for rental with the application of the following fees:

• For a single transit 0 ÷ 10 tons – free

• For a single transit over 10 tons – € 90,00/tons (i.e. 124.000 kg = 11.160,00 €)

• Parking for more than 3 days will incur an additional charge of 500,00 € / day

• For boats – 10 lei / day

To use the ramps, please contact Walter Tosto WTB (with at least 15 days’ notice) at the following contacts:

Phone: +40 314.201.060 (Monday to Friday, from 8:00 a.m. to 4 p.m.)

Fax: + 40 314.201.060

E-mail: office@wtb.ro

The pictures below show the quay before and after the renovation

We are equipped with a wide machine park and innovative technologies, which allow us to internally carry out all the critical production and logistic activities. As a result, the company is able to manufacture and transport products without weight and size limits.

| CRANES | ||

|---|---|---|

| Quantity | Weight | Location |

| 1 | 800 (400+400) tons | WTB – Bucharest |

| 1 | 400 tons | WTB – Bucharest |

| 3 | 160 tons | WTB – Bucharest |

| 2 | 60 tons | WTB – Bucharest |

| 5 | 50 tons | WTB – Bucharest |

| 1 | 32 tons | WTB – Bucharest |

| 2 | 300 tons | WTO – Oltenita |

| 1 | 60 tons | WTO – Oltenita |

| JIB CRANES | ||

|---|---|---|

| Q.ty | Length | Weight |

| 6 | 5,5 meters | 2 tons |

| 20 | 12 meters | 10 tons |

| 1 | 21 meters | 50 tons (under construction) |

Beveling Machine

VERRINA

Lenght: 20.000 mm

Thickness: 300 mm

Hydraulic Rolling Machine

Bending Roller Verrina

max length 4.000 mm

thk. 210 mm

yield strength material 280 MPa

Lathe Milling Machine

WFL-1

X: 720 mm

Y: 600 mm

Z: 3.150 mm

Cutting Machine

16.000 X 4.000 mm

Thk max 300 mm

Hydraulic Press

600 T

Max Diameter 5000 mm

Max Thickness 70 mm

Drilling Machine EMSIL

3 STS system drilling heads max. 80 mm

X: 6900 mm

Y: 4300 mm

Z: 1800 mm

W: 600 mm

Handling Table

Milling Machine

Including controller

Vertical Lathes:

IMUAB

Diam: 8.500 mm

Height: 5.000 mm

Weight: 100.000 kg

The welding process is the core of our manufacturing activities.

Our Welding Department is able to employ the following welding processes:

|

Welding Process employed |

Manual |

Automatic |

|

Shielded Metal-Arc welding – SMAW |

X |

|

|

Submerged-Arc Welding – SAW |

X |

|

|

Subm.-Arc Weld. with strips – SAW STRIP |

|

X |

|

SAW Double Wire – SAW Tandem |

|

X |

|

Gas Metal-Arc Welding – GMAW |

X |

X |

|

Gas Tungsten-Arc Welding – GTAW |

X |

X |

|

Flux-Cord Arc Welding – FCAW |

X |

X |

|

Electro Slag Welding – ESW |

|

X |

|

Plasma-Arc Welding – PAW |

|

X |

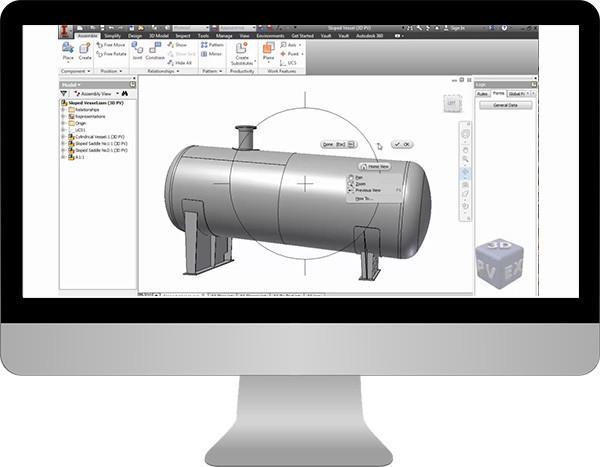

The full knowledge and the familiarity with all the existing design codes such as ASME, BS 5500, CODAP, Stoomwelzen, AD Merkblatt and GOST allow us to develop the best design from the mechanical point of view. Furthermore, the in-house presence of FEM experts, together with the several ANSYS licenses, make the Finite Element Analysis a powerful instrument in our hands, for the design of critical parts of the equipment.

In addition to the mechanical design, Walter Tosto WTB has strong skills in the development of the thermal and fluid-dynamic design starting from Process Data Sheets, ensuring all the required guarantees to our customers.

Our design activities include:

• 3D simulations

• Stress analysis by finite elements methods

• Fracture mechanics analysis

• Static analysis in steady and unsteady conditions

• Fatigue analysis

• Creep fatigue damage evaluation

• Thermo-hydraulic design of heat transfer systems

Design codes and standards

| ASME I | ASME III Ed.2007 Add. 2009 | ASME VIII Div.1 latest edition |

| ASME VIII Div.2 latest edition | ASME VIII Div.3 latest edition | PD 5500 |

| AD Merkblatt 2000 | VSR | STOOMWEZEN |

| SELO | API 579 – 1 ASME FFS-1 | API 620/650/660 |

| CODAP 2000 CODRES | HEI | GOST |

| IBR | TEMA | EN 13445 |

| IBC 2006 | UBC 97 | ABSA |

| ASCE / SEI 7-05 | BS 7910-2005 | EJMA 9TH Ed. |

| EN 1405 | ASME B 16.5 | ASME B 16.47 |

| API STD 6A | API 934 – 941 | NACE MR 0175/ ISO 15156-3 |

| RCC-M e RCC-MR – nuclear sector | EUR (European Utility Requirements) – nuclear sector | ABSA |

Main Design Softwares

| Finglow: PD5500 pressure vessels calculation software |

| Solid Edge: 3D drawing calculation software |

| Pro ENGINEER: parametric 3D drawing program |

| CATIA V5 R20: 3D drawing program |

| ANSYS: finite element analysis and CFD analysis |

| ASPEN Shell & Tube Exchanger Design Rating Software |

| Aspen Exchanger Mechanical Design Software |

| Sant’Ambrogio: mechanical calculation software for VSR, ASME VIII |

| Div. 1 + EJMA expansion joints module |

| ASME VIII Div. 2, AD 2000 Merkblatt + expansion joints module, WRC 107/297 |

| AUTO CAD AUTODESK: 2D drawing program |

Metrology softwares

| New River Kinematics: Spatial Analyzer |

| Innovmetric: Polyworks |

| Hexagon: Emscon, Tracker Pilot, RDS |

| Aberlink: 3D MKIII |

Thanks to our qualified personnel (ASME and ISO9712) and to our cutting-edge equipment, we are enabled to perform all Non Destructive Testing (NDT) checks in-house.

X-Ray NDT

For X-Ray NDT we own:

- 3 Iridium 192 sources with maximum capacity of 150Ci – up to 90mm thickness

- 2 Co60 sources with maximum capacity of 300Ci – up to 200mm thickness

- 1 Linear Accelerator LINATRON 2000 VARIAN SUA 8MeVi 2000 Rads / min – up to 300mm thickness

- 1 X-Ray instrument of 300V-3mA-600W maximum power – up to 40mm thickness

These activities are performed in two bunkers.

The large bunker has a wall thickness of 9 meters and is 31 meters long. The small bunker has a wall thickness of 6.5 meters and is 9 meters long.

Ultrasonic Testing (UT)

For Ultrasonic Testing we own 2 machines for UT time-of-flight diffraction technique (UT Tofd):

- Olympus Omniscan MXSN

- Alympus Omniscan MX2

For Manual UT the following tools are available:

- 2 Olympus Epoche 600

- 1 Olympus Epoche 650

- 2 Tools for UT Phased Array Olympus Omniscan MX2

We carry out the following superficial checks internally:

- Penetrant liquids

- Control with visible Magnetic Particles

- Control with fluorescent magnetic particles

Other checks:

- Hardness control with Salutron UCI3000 instrument

- Thickness check with Olympus 27MG instrument

- Ferrite check with Fisher ferritoscope

- Controls with Positive Material Identification (PMI) method

- Air tests and helium tests